Let's Talk About Your Needs

Subscribe Now! Get Awesome Monthly Posts

Make your business more successful with latest tips and updates for technologies

AI \ Use Cases \ AI Use Cases in Manufacturing

AI in predictive maintenance for the manufacturing industry, enhancing operational efficiency. Using advanced algorithms, the system analyzes historical data, equipment performance, and environmental factors to predict potential machinery failures. This proactive approach enables scheduled maintenance, minimizing downtime and production losses. Real-time monitoring allows for immediate intervention, preventing costly breakdowns. AI-driven predictive maintenance not only reduces maintenance costs, but also extends equipment lifespan. Futurism’s AI solution empowers manufacturers to transition from reactive to predictive maintenance, fostering a more resilient and cost-effective production environment in the rapidly evolving landscape of manufacturing technologies.

AI in supply chain optimization for manufacturing industry. By implementing advanced algorithms and machine learning, the solution predicts demand fluctuations, streamlines inventory management, and minimizes production delays. Real-time data analytics enhance decision-making, optimizing procurement processes and reducing costs. AI-driven predictive maintenance ensures efficient equipment performance, minimizing downtime. Through intelligent routing and scheduling, the system optimizes logistics, reducing lead times and enhancing overall supply chain efficiency. Futurism’s AI solution empowers manufacturers to adapt swiftly to market changes, improving resource allocation and fostering a responsive, resilient, and cost-effective manufacturing ecosystem.

AI for customization and personalization in the manufacturing industry, enhancing efficiency and customer satisfaction. Through machine learning algorithms, the system analyzes historical data, user preferences, and market trends to tailor production processes. This ensures the creation of highly customized products with minimal lead times. AI-driven predictive analytics also aid in demand forecasting, optimizing inventory levels, and reducing wastage. Real-time monitoring and feedback mechanisms further refine customization, adapting to evolving consumer needs. Futurism’s AI solutions revolutionize manufacturing, offering a seamless blend of precision, agility, and customer-centricity, ultimately propelling the industry into a new era of personalized production.

AI in production planning and scheduling for streamlined manufacturing. The system analyzes historical data, market trends, and real-time production metrics to optimize scheduling, ensuring efficient resource allocation, minimizing downtime. Machine learning algorithms predict potential disruptions, enabling proactive decision-making. AI-driven demand forecasting enhances inventory management, reducing overstock and shortages. This innovative approach not only increases productivity but also improves overall operational resilience. Futurism AI empowers manufacturers with agile, data-driven decision support, fostering adaptability in a dynamic market environment while maximizing resource utilization and maintaining cost-effectiveness.

Employ Digital Twins technology to create virtual replicas of manufacturing processes and products. These AI-powered models simulate real-world operations, allowing for process optimization, scenario testing, and the identification of efficiency improvements without disrupting actual production. AI and RPA in the manufacturing industry to streamline operations. AI-powered predictive maintenance analyzes equipment data, minimizing downtime and optimizing production. RPA automates repetitive tasks, reducing human errors in assembly lines and inventory management. The system utilizes machine learning algorithms to enhance demand forecasting, ensuring efficient resource allocation. Real-time data analytics provide insights for process optimization, enabling agile decision-making. Overall, this synergy of AI and RPA improves productivity, lowers operational costs, and enhances overall efficiency in the manufacturing workflow.

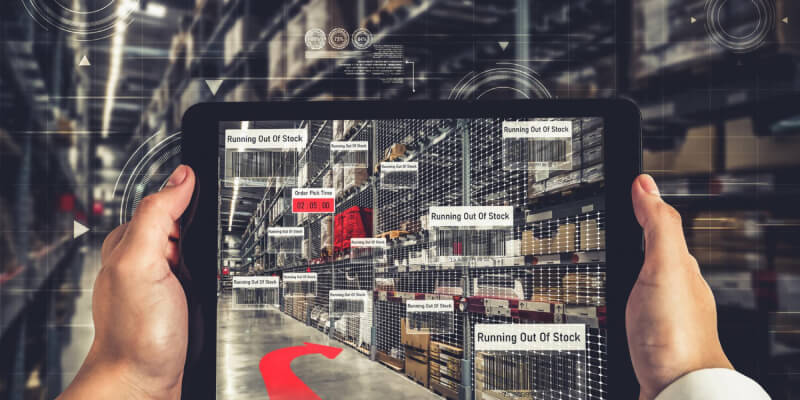

Leverage AI for intelligent warehouse management, optimizing inventory control, and automating storage and retrieval processes. AI algorithms can predict inventory needs, optimize stock levels, and guide autonomous robots for efficient material handling and storage. Enhance supply chain visibility and resilience using AI to analyze and predict supply chain disruptions. By integrating data from various sources, AI provides actionable insights for risk mitigation, alternative sourcing strategies, and dynamic adjustment of supply chain operations.

AI-driven workforce management solution revolutionizes manufacturing operations. Leveraging advanced data science to optimize shift scheduling, predict peak production times and employee fatigue. The system considers historical data, real-time production metrics, and external factors to ensure an agile workforce. Predictive analytics aids in proactive maintenance, reducing downtime. Additionally, AI assesses skill sets and recommends training programs for personnel development. This results in enhanced productivity, reduced operational costs, and improved employee satisfaction.